When you take a generic drug, you expect it to work just like the brand-name version. That’s not luck. It’s the result of strict cleanroom standards that control every particle, every microbe, and every human movement inside the manufacturing space. For generic drug makers, meeting these standards isn’t optional-it’s the difference between a life-saving medicine and a dangerous failure.

Why Cleanrooms Matter More for Generic Drugs

Generic drugs aren’t copies. They’re required to be bioequivalent to the original brand-name drug. That means they must deliver the same amount of active ingredient at the same rate into your bloodstream. But here’s the catch: if the manufacturing environment isn’t clean enough, contamination can change how the drug behaves-even if the formula is identical. The FDA and other global regulators don’t just check the final pill. They inspect the room where it was made. A single airborne particle carrying bacteria can ruin a batch of injectable drugs. In 2012, a compounding pharmacy’s dirty environment led to a meningitis outbreak that killed 64 people. That tragedy reshaped how everyone thinks about cleanrooms. For generic manufacturers, the stakes are even higher. They operate on thin margins-15% to 20% gross profit-while brand-name companies often make 70% to 80%. Yet they’re held to the same cleanroom rules. One failed inspection can mean a $100 million recall, like the one Aurobindo Pharma faced in 2022. No other industry faces this kind of cost-pressure paired with zero tolerance for error.The Four Levels of Cleanroom Grades

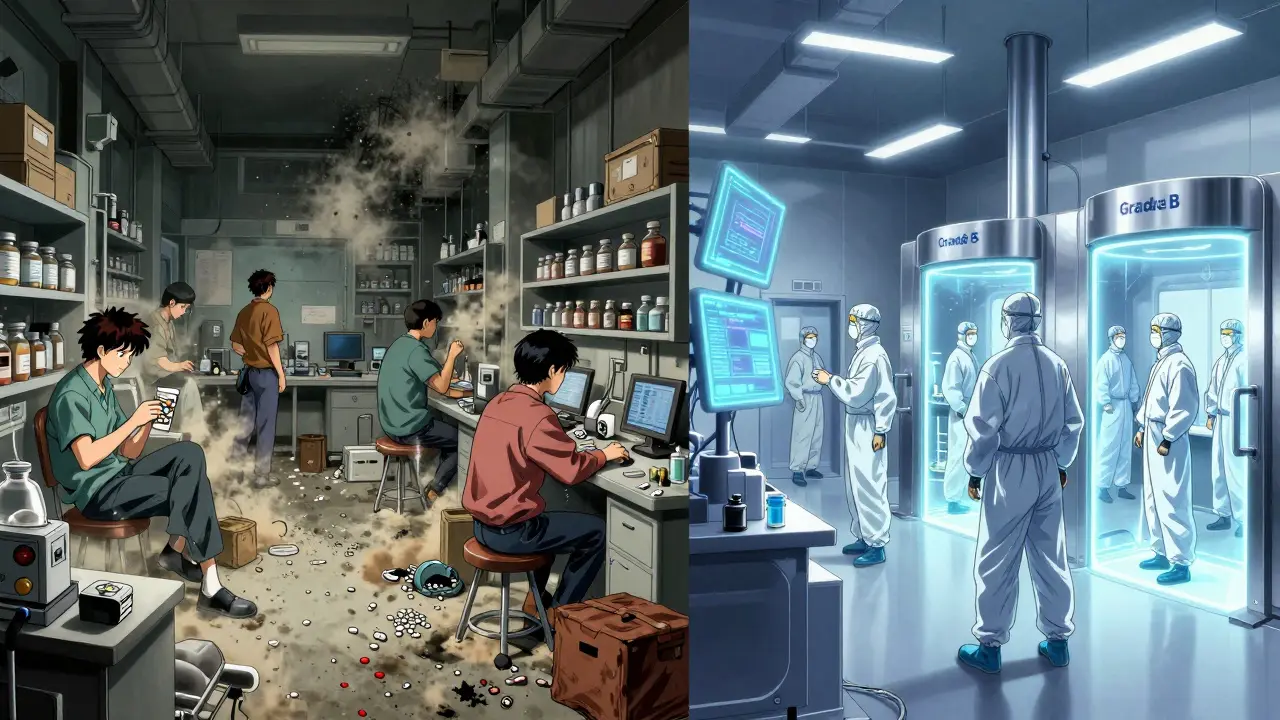

Cleanrooms aren’t all the same. They’re classified into four grades, each with exact particle and microbe limits. These aren’t suggestions-they’re legally enforceable standards under EU GMP Annex 1 and FDA cGMP rules.- Grade A (ISO Class 5): Used for sterile filling operations. No more than 3,520 particles larger than 0.5 micrometers per cubic meter. Air moves in a perfect, unidirectional flow at 0.36-0.54 meters per second. Think of it like a surgical suite for pills and injections.

- Grade B (ISO Class 5 at rest, ISO Class 7 during operation): The background area for Grade A. It’s where staff prepare materials before entering the sterile zone. Particle limits jump to 3.5 million during operations, but continuous monitoring is required.

- Grade C (ISO Class 7 at rest, ISO Class 8 during operation): For non-sterile preparation steps. Allows up to 35 million particles during operations. Common in tablet manufacturing where contamination risk is lower.

- Grade D (ISO Class 8 at rest): The lowest classification. Used for packaging and final labeling. No operational particle limit, but still requires 10 air changes per hour.

How Cleanrooms Are Built and Maintained

Building a Grade A cleanroom costs between $250 and $500 per square foot. That’s not just filters and walls. It’s a full system: high-efficiency particulate air (HEPA) filters that trap 99.995% of particles at 0.3 micrometers, laminar airflow hoods, automated pressure controls, and real-time particle counters that beep if something goes wrong. The air doesn’t just circulate-it’s pushed. In Grade A zones, air flows downward in a smooth, unbroken stream like water in a waterfall. This pushes particles away from the product instead of letting them settle. Any turbulence-like a person turning too fast-can disrupt it. Personnel are the biggest risk. A single person sheds up to 100,000 skin flakes per minute. That’s why gowning procedures take 40 to 60 hours to train. Staff wear full-body suits, hoods, masks, double gloves, and shoe covers. They enter through airlocks. They move slowly. They never turn their back to the product. One slip-up can cost millions. Validation is another huge hurdle. Before a cleanroom can produce medicine, it must pass three rounds of testing over 3-6 months. This includes measuring airflow, particle counts, microbial growth, and pressure differences. Documentation alone can require 15-20 standard operating procedures. If one step is missing, the FDA will issue a warning letter.

Global Rules, Different Approaches

The U.S., Europe, and Japan all agree on the goal: no contamination. But they don’t always agree on the details. The European Union spells out exact ISO equivalents for each grade in Annex 1 (updated August 2023). The FDA doesn’t. Instead, it says facilities must be designed to prevent contamination-without naming ISO classes. That gives manufacturers more flexibility, but also more uncertainty during inspections. In the U.S., USP Chapter <797> applies to pharmacies compounding sterile drugs. It allows ISO Class 7 buffer rooms. That’s two grades below what’s required for manufacturing sterile injectables. This gap has caused confusion, especially when generic companies supply both hospitals and retail pharmacies. Japan requires extra monitoring at 1.0 micrometer particle size-a level most other countries ignore. India’s manufacturers spend an average of $4.2 million per facility to meet EU standards, compared to $2.8 million in the U.S., because older infrastructure makes upgrades harder. Despite these differences, global alignment is growing. The FDA has signaled it will adopt key parts of the new EU Annex 1 rules. That means manufacturers who want to sell in both markets must now design for the strictest standard.Costs vs. Consequences

Cleanrooms are expensive. A Pfizer facility spent $2.3 million and 14 months upgrading from Grade C to Grade B for a generic cancer drug. But they prevented 17 out-of-spec batches each year-worth $8.5 million. That’s a clear return on investment. For small generic makers, the cost can be crushing. One Reddit user described how maintaining Grade A for a $0.50-per-unit heparin syringe made their business unprofitable after two FDA inspections flagged minor particle spikes. They shut down. The International Society for Pharmaceutical Engineering found that facilities following full EU Annex 1 had 27% fewer quality issues-but 35% higher operating costs. That’s why some experts question if Grade C is needed for oral solids. A 2020 study showed identical dissolution profiles between Grade D and Grade C facilities making pills. But regulators still require Grade C. Why? Because the risk isn’t just about the pill-it’s about what happens if the next batch has a hidden contaminant.What’s Changing in 2025 and Beyond

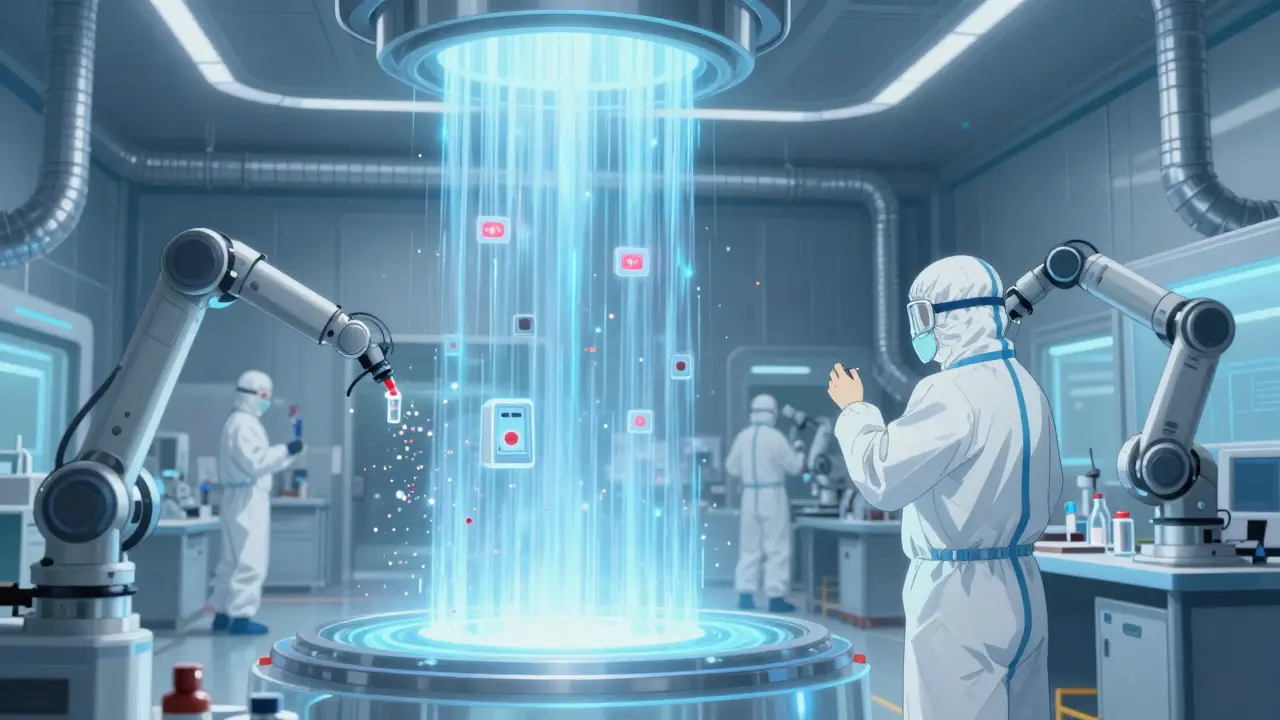

The biggest shift? Automation. Robots are replacing humans in Grade A areas. AI-powered sensors now monitor air quality in real time, alerting teams before particles spike. By 2028, McKinsey predicts automation will cut cleanroom operating costs by 25-30%. New types of drugs are forcing new standards. Biosimilars, complex inhalers, and injectable biologics need environments beyond traditional grades. The FDA expects 50% of new generic applications by 2025 to require Grade A/B cleanrooms-up from 35% in 2022. The FDA’s Generic Drug User Fee Amendments (GDUFA) III, running through 2027, includes $15 million for training inspectors in cleanroom evaluation. That’s a signal: inspections are getting tougher, not easier.

Real-World Successes and Failures

Teva’s generic version of Copaxone, a multiple sclerosis drug, was rejected twice because of contamination in its Grade A area. They installed isolator technology-sealed robotic systems that handle sterile filling without human contact. Contamination events dropped from 12 per year to 2. Approval came after. Aurobindo Pharma’s 2022 recall of sterile injectables cost $137 million. Why? Inadequate monitoring in Grade B zones. The FDA found particle counts exceeded limits for months. No one noticed. No alarms triggered. No one checked the logs. These aren’t outliers. In 2022, 42% of complete response letters for sterile generics cited environmental monitoring failures-up from 31% in 2018. The message is clear: regulators are watching closer than ever.What You Can Do to Stay Compliant

If you’re in generic drug manufacturing, here’s what works:- Start with a contamination control strategy-not just a checklist. Ask: Where could contamination enter? Who touches it? What fails first?

- Invest in continuous monitoring. Don’t wait for quarterly tests. Real-time alerts save batches.

- Train staff like pilots. Gowning isn’t a formality-it’s a life-or-death skill.

- Use validated software for documentation. Paper logs are a red flag for inspectors.

- Don’t cut corners on HVAC. It’s the backbone of every cleanroom.

Final Thought: Cleanrooms Are the Invisible Guardian

You’ll never see a cleanroom. You’ll never know how many lives it saved. But every time a generic drug works exactly as it should-without side effects, without failure-it’s because someone controlled the air, the temperature, the movement, the gowning, the filters, the alarms. Cleanroom standards aren’t about perfection. They’re about control. And in pharmaceuticals, control is the only thing that stands between a medicine and a tragedy.What is the difference between Grade A and Grade B cleanrooms in generic drug manufacturing?

Grade A is the highest level, used for direct sterile filling operations like injectables. It allows no more than 3,520 particles ≥0.5μm per cubic meter and requires unidirectional airflow. Grade B is the surrounding area that supports Grade A. At rest, it matches Grade A’s limits, but during operations, it allows up to 3.5 million particles. Grade B still requires continuous monitoring, while Grade A demands absolute control.

Do generic drug manufacturers need to meet the same cleanroom standards as brand-name companies?

Yes. Regulatory agencies like the FDA and EMA require generic drugs to be bioequivalent to the original product, which includes matching manufacturing quality. If the brand-name drug is made in a Grade A environment, the generic must be too. There’s no exception for cost or scale.

How often are cleanrooms inspected by regulators?

Inspections happen every 2-3 years for most facilities, but high-risk sites like sterile injectable manufacturers can be inspected annually. After a warning letter or recall, inspections can occur every 6 months. The FDA increased its focus on cleanroom compliance, with 63% of all 2022 warning letters tied to GMP violations.

Can a cleanroom be too clean for some generic drugs?

For non-sterile oral solids like tablets, some experts argue that Grade C or even Grade D is sufficient. A 2020 study showed no difference in drug performance between Grade D and Grade C facilities. But regulators still require Grade C because contamination risk can’t be fully predicted-especially with complex formulations or moisture-sensitive ingredients.

What happens if a cleanroom fails an inspection?

The FDA issues a Form 483 listing observations. If unresolved, it leads to a warning letter. Continued violations can trigger import alerts, product recalls, or consent decrees-like Aurobindo’s $137 million recall. In extreme cases, the facility is shut down until it passes re-inspection, which can take over a year.

Are there cheaper alternatives to traditional cleanrooms?

Not for sterile products. For non-sterile drugs, some manufacturers use localized HEPA filtration or isolators to reduce room-wide requirements. But for injectables, ophthalmics, or inhalers, there’s no substitute for full Grade A/B environments. Emerging tech like single-use systems and robotics may lower long-term costs, but they still require certified environments.

Allie Lehto

January 24, 2026 AT 12:40Henry Jenkins

January 24, 2026 AT 18:18John Wippler

January 26, 2026 AT 14:44Kipper Pickens

January 27, 2026 AT 15:25Aurelie L.

January 27, 2026 AT 15:34